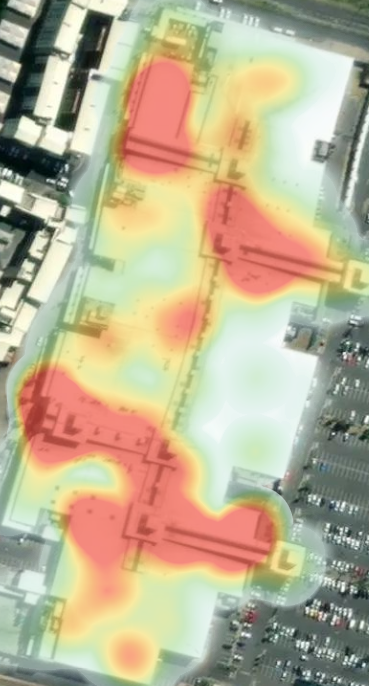

Predictive models for maintenance servicesPredictive maintenance based on big data and geospatial data seeks to define the best time to perform work on an asset, so that maintenance frequency is as low as possible and reliability is as high as possible without unnecessary costs.Tuesday, March 8, 2022

Maintenance teams are beginning to embrace the use of big data and predictive modeling to improve performance, which helps establish maintenance programs that reduce downtime and save maintenance costs, while extending the life of their equipment, reducing unnecessary tasks and optimizing spare parts inventory. ¿Busca soluciones de inteligencia comercial para su empresa?Do you need to implement predictive models to optimize your maintenance processes? Contact us!Need assistance? Contact us

(506) 4001-6423

Global Supply Chain Crisis?October 2021 COVID-19 and climate change have directly impacted the supply chains of the sectors and industries that generate the most economic output. How to Use Transportation Analytics and its benefitsSeptember 2021 Through data analytics it's possible to improve vehicle performance, reduce costs, improve processes, establish strategies, optimize routes and times, and foresee and identify problems, among others. Supply Chains Predictive Analytic benefitsSeptember 2021 Unlike historical analytics, predictive supply chain analytics allows you to anticipate and prepare for the future, taking out the conjectures planning processes and improving decision making. Big Data Applied to the Port SectorJuly 2021 In today's digital age, competition in the port sector has led companies to constantly invest in solutions that help them increase productivity and reduce overall costs, consequently, the demand for advanced solutions, such as maritime data analytics, is growing at an impressive rate among commercial shippers and other end users.

×

ok |

|

×

![]()

español

español